BUILDINGS UP TO 7 STOPS – ECONOMICAL SOLUTION

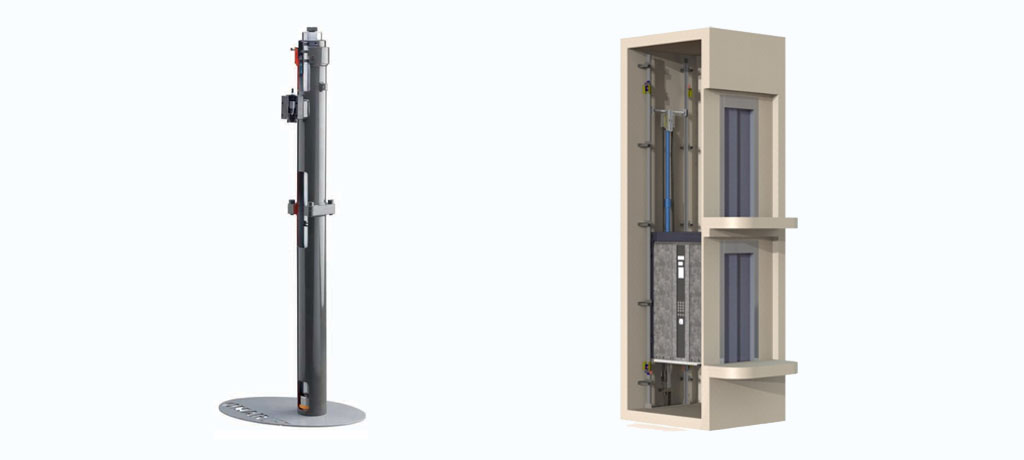

Hydraulic lifts have been frequently used in recent years and have a wide range of applications in small or medium height buildings.

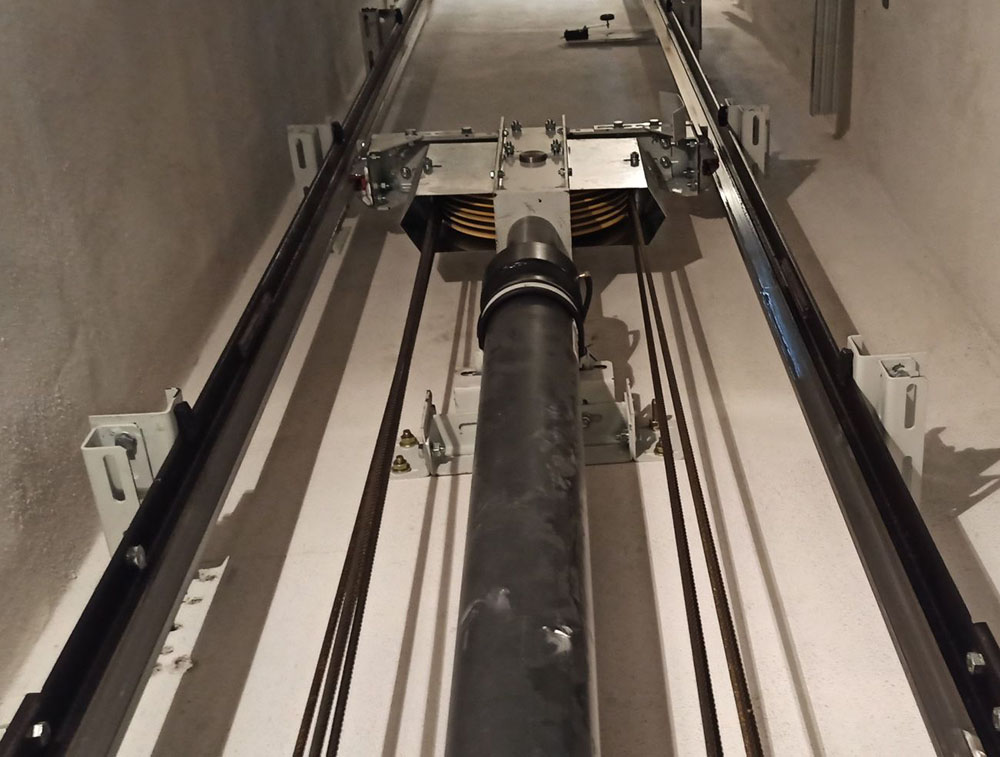

The movement is made with the help of a pump that channels special oil into a hydraulic Piston, which in turn moves the cabin directly or indirectly through pulleys & cables.

Hydraulic Lifts provide incredible reliability at a very reasonable cost, short installation time, low maintenance & long life.

Technical Specifications:

- Load/Capacity: 300-1600 kgr (4 to 21 people)

- Maximum Speed: 0.75 m/sec

- Maximum Distance: 21m

- Maximum Number of Stops: 8

Pros

- Incredible reliability at a very reasonable cost

- Short installation time

- Possibility of evacuation in case of interruption of a power stop

- Flexibility in the location of the machine room in the Basement / top floor

- Low noise level

- Fewer mechanical parts

- Long life service

Cons

- Not suitable for multi-storey buildings & high traffic facilities

- Changes in the position of the Cabin at extreme temperatures & in case of leaks

- Relatively low speed

Hydraulic lifts with i valve

The I Valve is a revolutionary innovation from Bucher Hydraulics.

This particular type of lift is a technologically advanced version of the hydraulic lift.

It is a complete control system combining (in both climb and descent), temperature / pressure sensors & high precision speed controllers to achieve superior motion quality.

This valve contains a built-in Safety Valve A3.

At the same time, up to 30% energy is saved compared to a conventional hydraulic lift.

Hydraulic lifts with VVVF (inverter)

It is not just a hydraulic pump controlled by an inverter, but a complete control system combining the inverter (during climb & descent), temperature / pressure sensors & high precision speed controllers to achieve superior movement quality.

Pros

- Energy saving of up to 30%

- Greater level of safety

- Continuous smooth travel curve, regardless of load and temperature

- In many cases no oil cooling is needed

- The automatic monitoring function guarantees full compliance with the A3 community directive.

- Smooth acceleration and deceleration as well as ride quality

Additional advantages compared to a conventional hydraulic lift

- Energy saving of up to 30%.

- Cabin position accuracy ± 3 mm.

- The “iTeach” algorithm provides continuous control of the travel curve

- No cosine correction device is needed.

Cons: Relatively new technology

For more information call us at +30 2410 237726